Corrugated Flat

We produce diecutting tools for all types of diecutting machines. The end user’s increased their demands on the workability of the packaging for the converting lines. In the corrugated industry multinationals are increasingly

purchasing at a European level. In light of this, standardization of performance will be achieved and subsequently optimized.

Steel counters

More and more jobs are diecutted with a steel counter plate instead of pertinax counter plates. Whereas previously, only large quantities were diecutted with steel counter plates, it is now clearly the tendency that shorter runs are also being diecutted with steel counter plates. The result is greater accuracy and a cleaner package; this is a must, particularly for the food industry. The speed and efficiency on the folding/gluing machines

was additionally increased

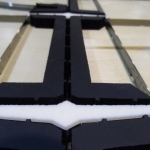

Topmatrix

Within the corrugated industry, the demands on packaging are ever increasing. Especially for the food industry, many criteria have to be met, and are worked amongst others via the HACCP norms. Cleaner packages are a must. In addition packing is produced with a consistently lower grammage, making the packaging more vulnerable. DieVision has the answer, the “TopMatrix” cutting die. DieVision has this license for the Netherlands, Belgium, and Poland and through Bieling& Petsche for Austria, Hungary and South Germany. With such an implementation, using lower grammage board, a cleaner package was produced without tearing of the creasing lines and inside liners.

Stripping

The most inhibiting factor in the diecutting process is the stripping. Stability in the stripping is essential. DieVision offers for this, different stripping systems including, Conventional, Dyna-strip, PinPoint and Strip- Clip, or a combination thereof. It is becoming more important to quickly changeover the diecutter and to diecut without lower pins. However, the waste must be completely stripped. For this there are different stripping systems or combinations available.

Topmatrix Technology

DieVision is licensee of this patented technology for the Benelux and Poland.

This technology creates a considerable reduction of diecutting dust and “angel hair” and prevents tearing of the board during the diecutting process. This is especially beneficial for producers of packaging for the food industry, in order to meet the rigorous demands of their customers.

Benefits: Improved quality of creasing (it is not necessary to apply creasing matrixes).

- Improved quality of scoring (it is not necessary to apply creasestrips)

- Reduction in time taken to prepare for the machine tool.

- Saving on costs for creasestrips

- Substantial decrease of breaking cardboard close to the cut and crease line, even with the worst qualities.

- Cracks of all kinds, get eliminated, or vastly reduced.

- Slimmed grammages, can be used without getting more diecutting problems.

- By a uniform pressure distribution, the possibility of reducing the pressure in the cutting area.

- Extending the life of both die and the cutting machine.

- Thanks to the stabilization of the sheet during the cutting, the number of required “nicks” are reduced.

- A cleaner package

- Improving stripping system which the waste is removed.

- Stable transport of the components

DieVision heeft de volgende categorieën: