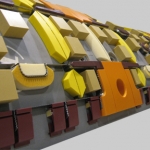

Rotary Dies

Rotary die cutting is still a growing market in Europe. Existing flatbed die packages are increasingly shifted to rotary die cutting machines. A higher output stands at the basis. The combination of increasingly precise laser cut dies, with improved rotary diecutting machines (particularly the modification of the anvils), guarantees the quality of the packaging. Size differences that occurred in rotary die cutting are greatly reduced. Our philosophy is not just the production of the diecut tool, but to come to an overall solution. Specialists assess the layout of the packaging and the nesting on the cutting die. Sometimes with small adjustments a greater improvement of efficiency in the rotary die process can be achieved, so there can be a higher output. Innovative thinking and testing with the customers on the production lines are included in our service. DieVision is one of the few manufacturers of rotary dies in the Benelux and has over 15 different cylinder diameters in its assortment.

Steel to steel

Steel on Steel Rotary die cutting is still a growing market in Europe.

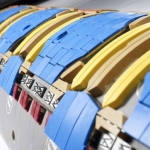

Trimsaver™

How it works:

It involves a 3-step process for perfect control and a perfect cut, bump after bump:

- Under pressure: The pressure is applied to the entire area of the trim area against the anvil.

- Blocking the combination of its high-tech features, blocks each space where a small piece of solid waste may get stuck.

- Ejection: The Trim Saver is designed for powerful ejecting, even of the smallest piece of waste

This animation shows the 3-step process (pressuring, blocking and ejecting). Please note that there is a short pause between each step:

Voor meer informatie over Trimsaver klikt u hier.

DieVision heeft de volgende categorieën: